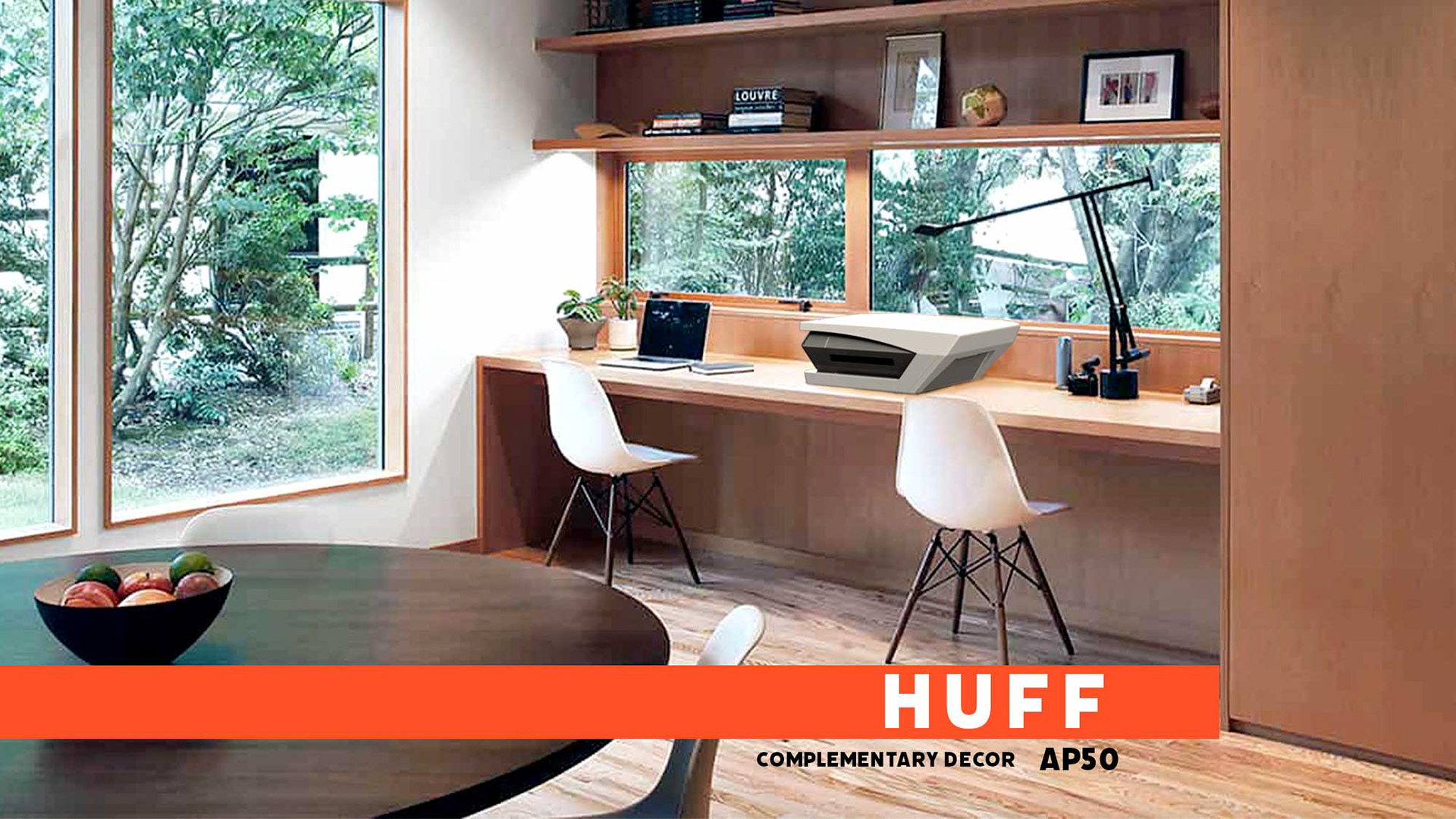

AP50: An all-in-one printer that embodies the blissful blend of function and aesthetics; an elegant exterior is combined with the print, copy, & scan abilities of a professional printer, allowing the user ultimate flexibility for both work and artistic experience

THE REASONING

Printers often occupy the extremes of the practicality/aesthetics dichotomy; one can rarely, if ever, get a machine that is both professionally capable & appealing to look at. Why not make printers objects individuals would be proud to display? Have consumers reshape their purchase decision from dread for where to put it, to pride in having acquired a beautiful piece of design

THE DESIGN

Seen below, AP50 can easily integrate into any space, offering consumers a print experience that seamlessly complements daily life

With an input storage of half a ream of paper (250 sheets), users are able to print more with less need for refills. Capillary ink storage & oversized cartridges make ink refills easy, infrequent, & more cost effective

INK STORAGE

INPUT & OUTPUT TRAYS

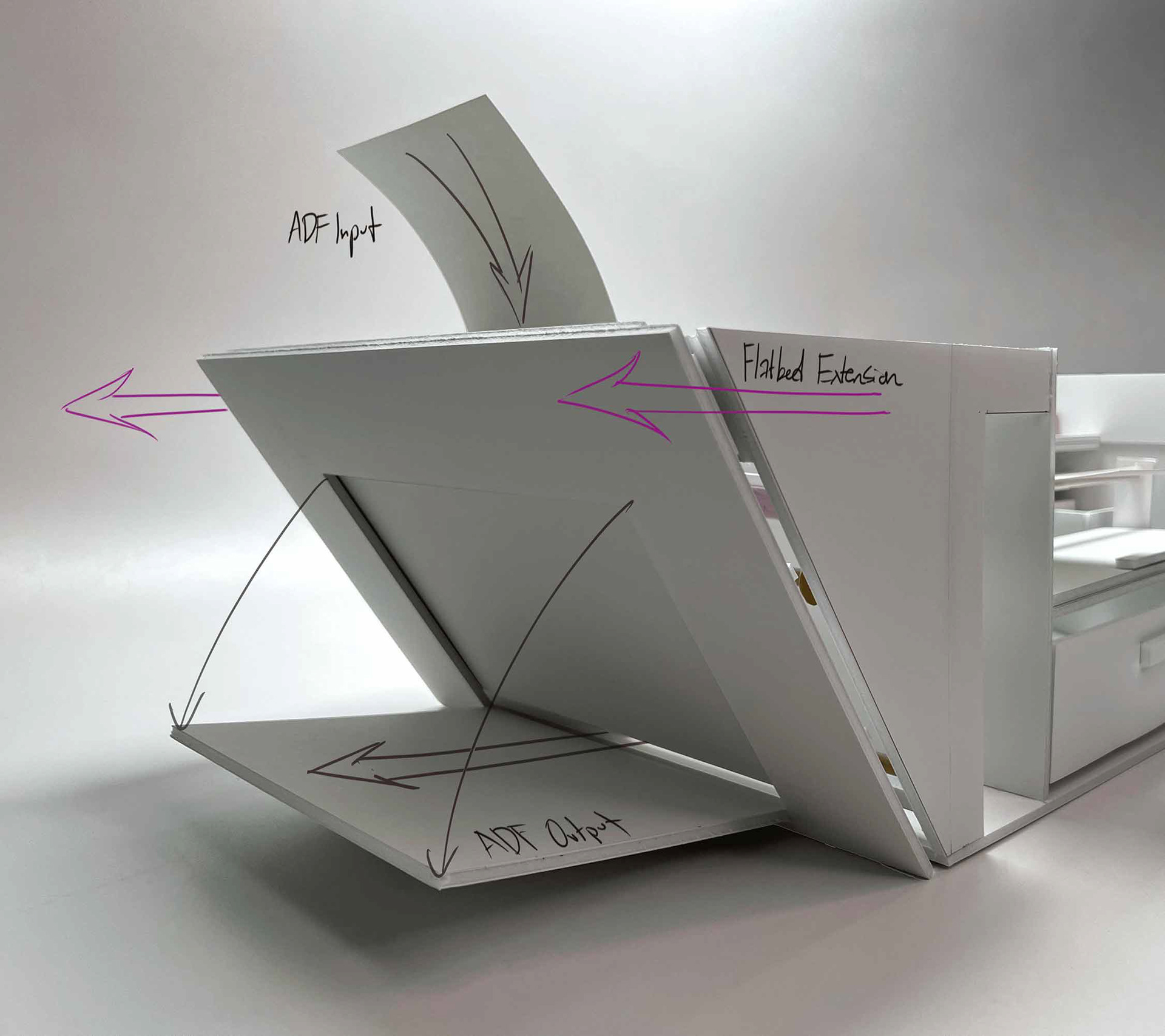

Scanning documents using the ADF is just as simple. With integrated input & output trays, AP50 can double-sided scan & copy documents up to 35 sheets in size.

ADF SCANNING

ADF OPENING OPERATION

For detailed scans, the integrated, side-access flatbed allows for scanning of documents up to 11"x14". A push activated control panel maintains AP50's sleek look while providing a simple and comprehensive overview of its capabilities.

CONTROLS EXTENSION (PUSH ACTIVATED)

FLATBED EXTENSION (PULL ACTIVATED)

TARGET MARKET

Those who require greater than average print usage, who value practicality, ease of use, and aesthetics equally

AP50 is seen positioned between utilitarian & artistic, reflecting its practicality, and leans towards being Harmonious in design, reflecting the consumer's appreciation of aesthetics

RESEARCH

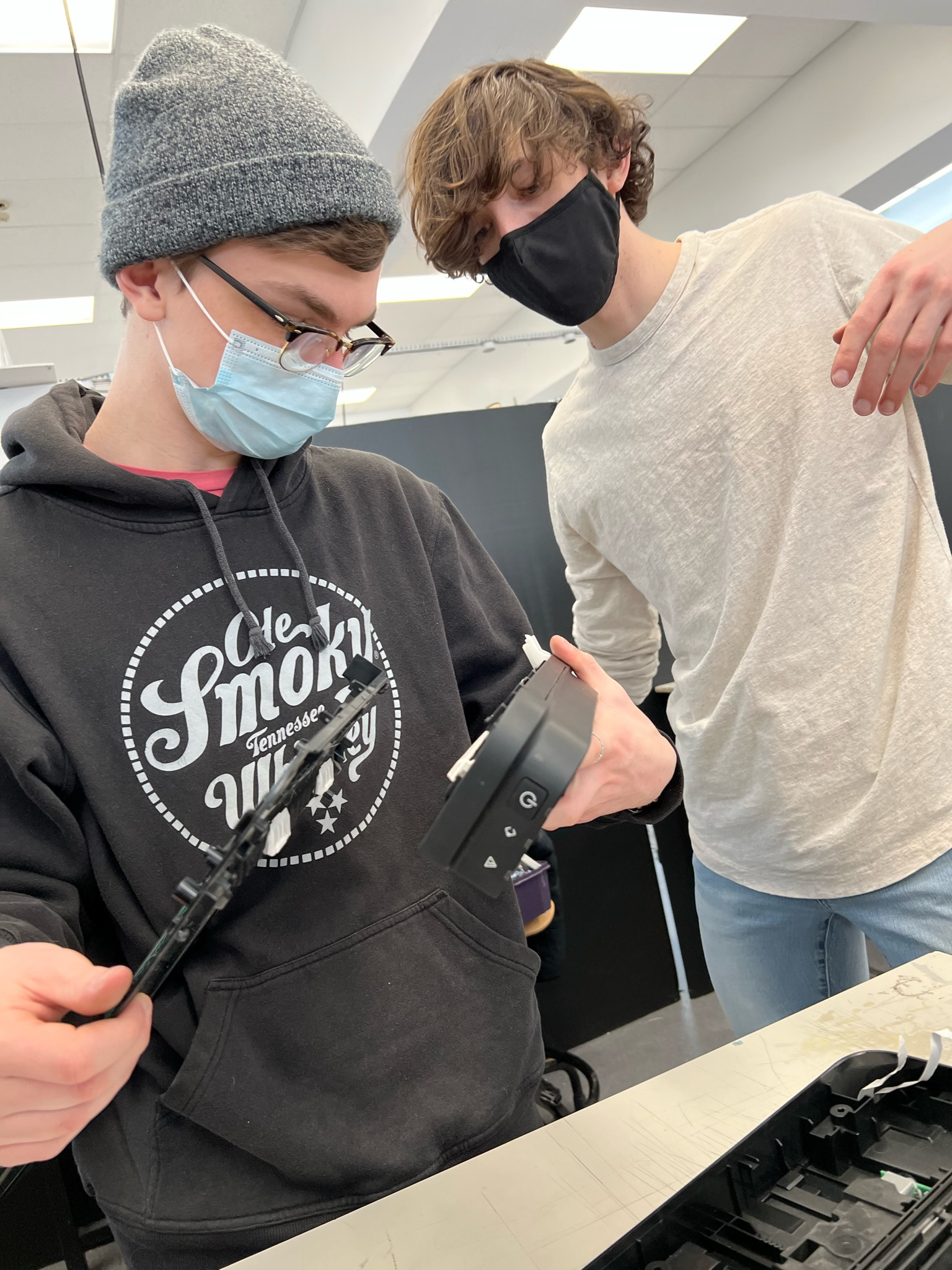

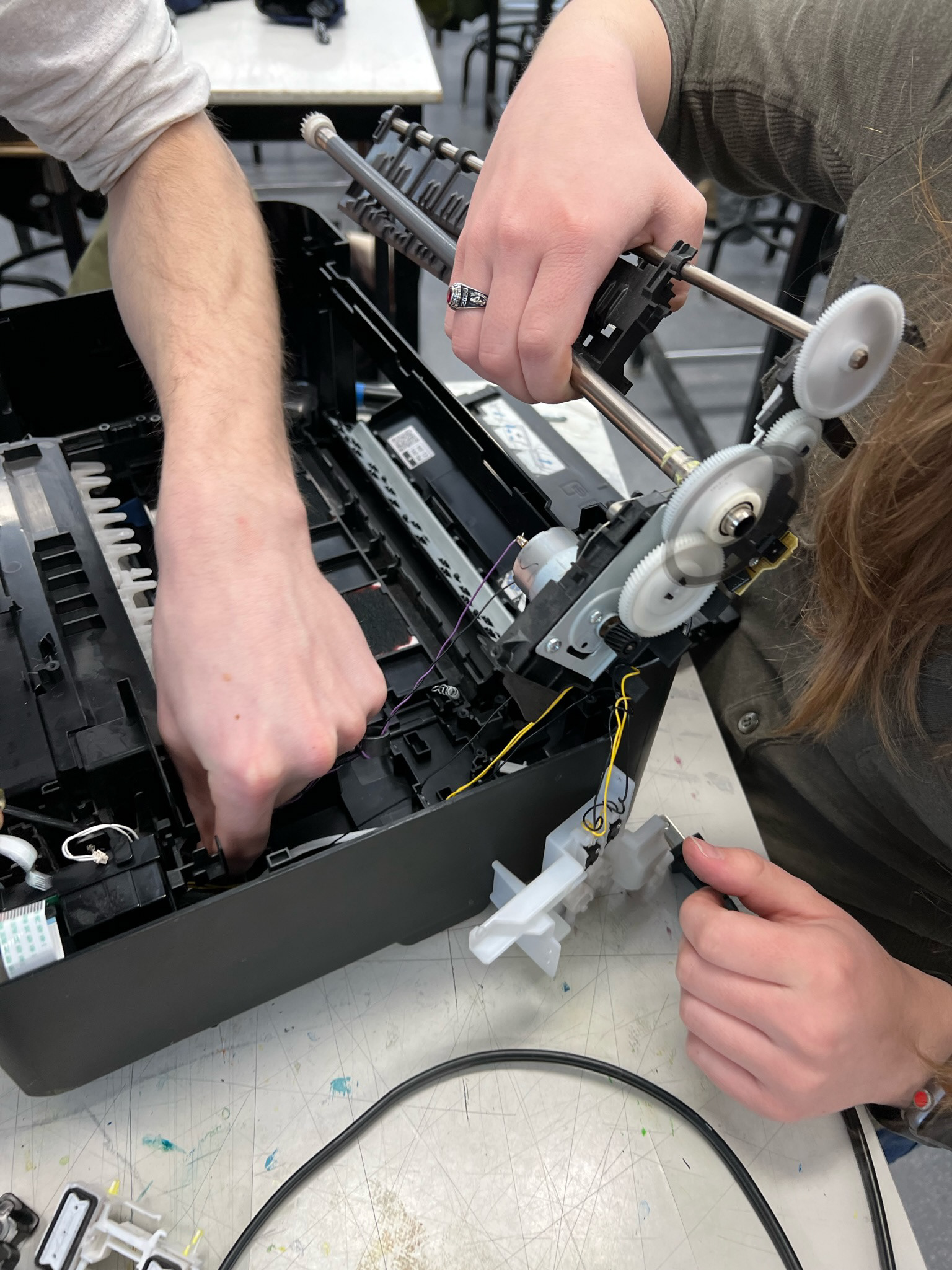

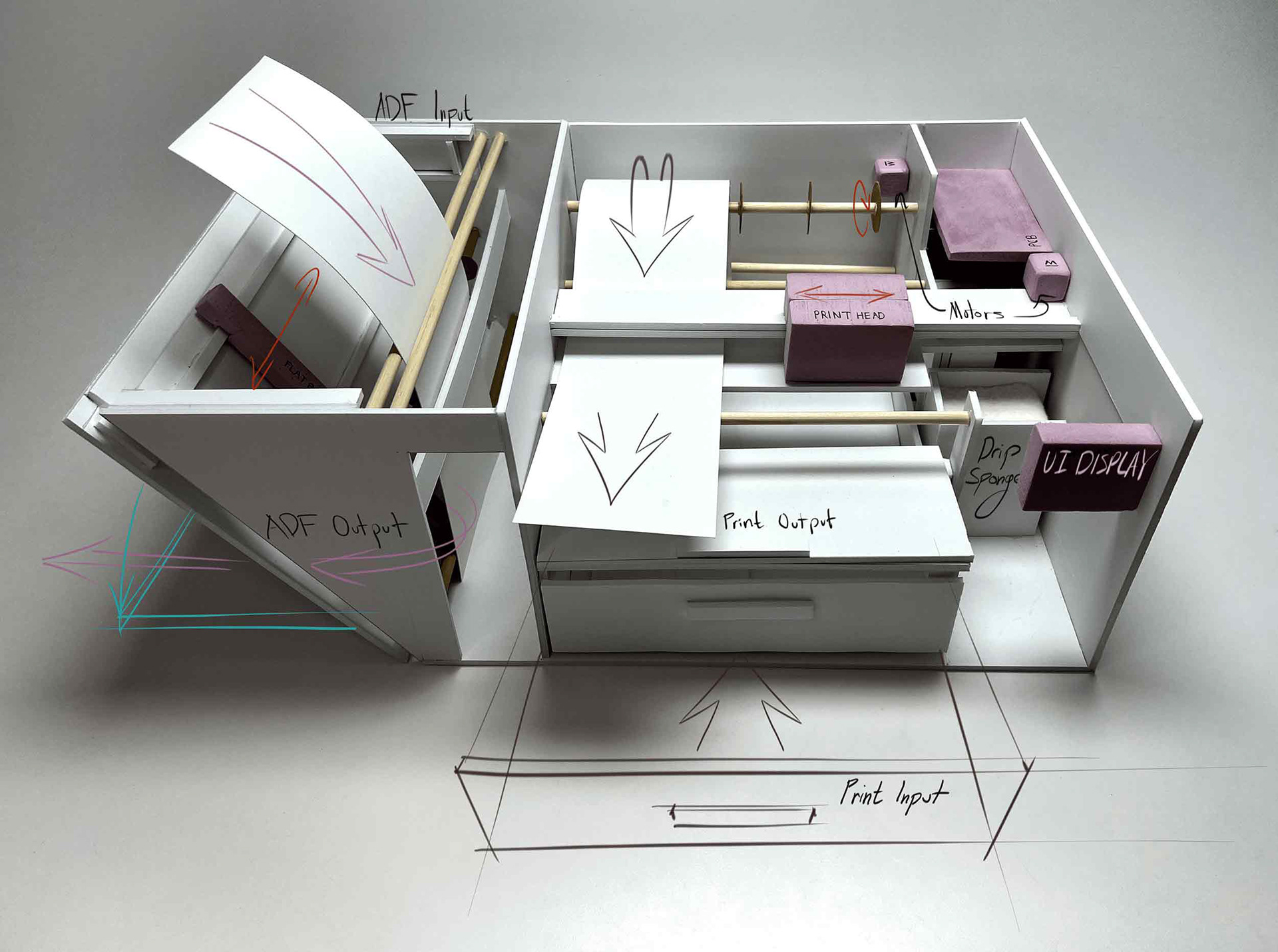

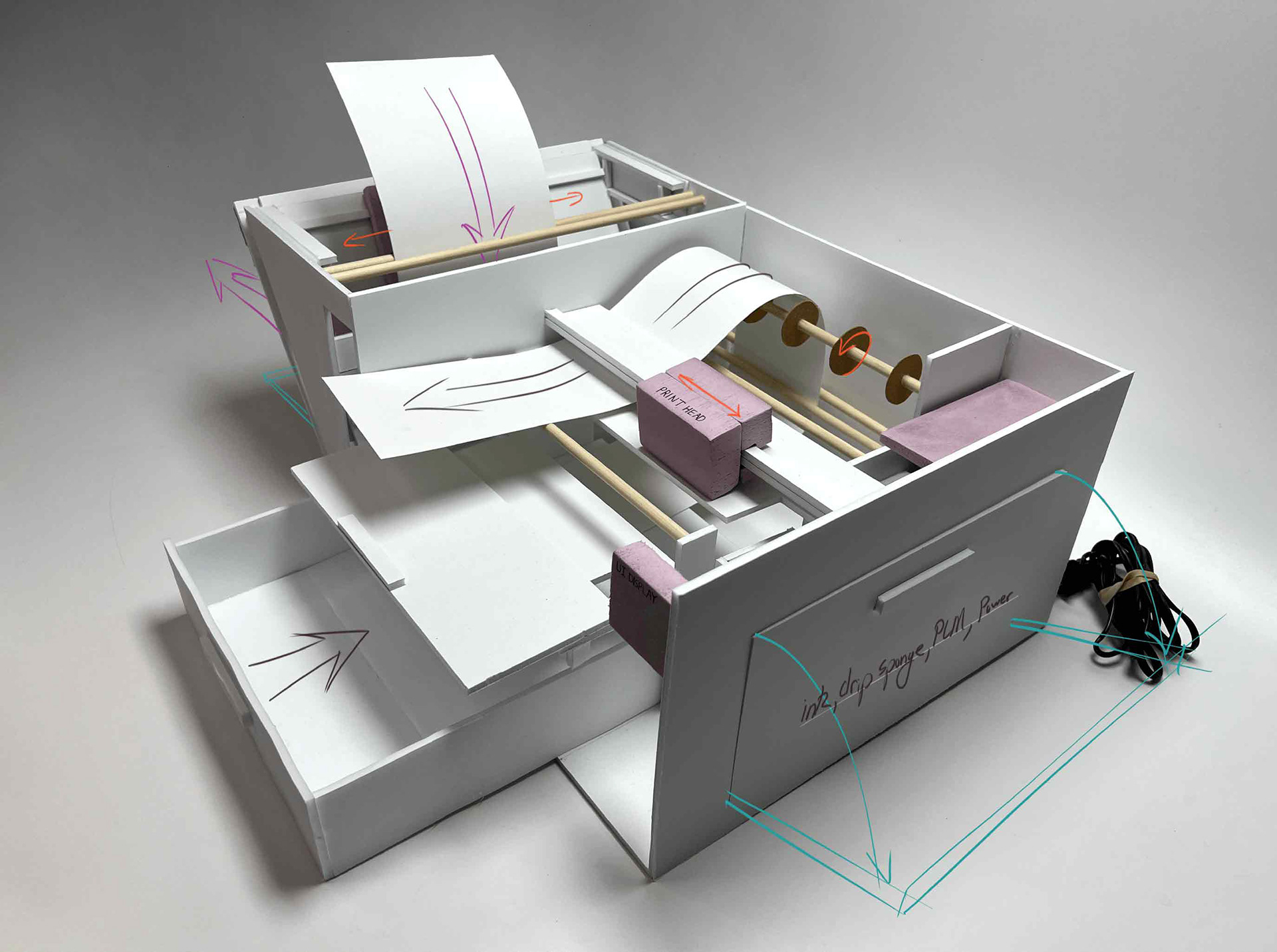

Divided Into teams of 3, each team was given a printer to disassemble and tasked to determine not only how a printer functions, but determine which components were most crucial and must be included in our own renditions

Shown: Mason Strange & Myself

Shown: Alyssa Tenny & Mason Strange

Shown: Myself and Alyssa Tenny

Internal Components were the first Constraints to Consider as they would Ultimately inform the final geometry of the outer facade. Previous Hands-On Research & exploration of current products on the market informed their development

INTERNAL COMPONENTS

A preliminary component model, seen below, was created to better understand physical & operational constraints as well as the proposed overall dimensions

OUTER FACADE

Using the internal component model as a template, the outer facade began to take form; a half scale model was carved of foam and used as an underlay for more refined iterations

1/2 Scale Outer Model

Refined Digital Drawings of Exterior

Full Scale Exterior Foamcore Model

Full Scale CAD Model of Exterior With Working Components

Successive iterations culminated in fully realized physical and computer models, seen above, and ultimately informed the final renders and ad campaign

HUFF - AP50 2022 22 x 16 x 7.5 INCHES 6 WEEKS